he Intelligent Fan Controller is designed to control the noise generated by the fans inside your computer. It does this by varying their speed based on temperatures measured inside the case. When it is cool the fans will run slowly and they will only speed up when needed… when your computer is running hot.

Anyone with a noisy computer, especially a Media Centre system in the lounge room, will benefit from this project. After installing this device, my computer is now so quiet that I can hardly tell that it is running – and that is a blessed relief.

- Configurable speed control based on temperatures measured inside your computer

- Control up to eight fans and measure up to four temperatures

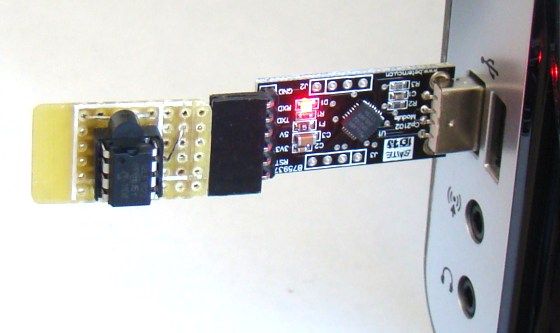

- USB interface and Windows software for setup and monitoring

- It will run independently without the Windows software (once it has been configured)

- Cheap – The cost for all the parts is about $48

The Intelligent Fan Controller was featured in the July 2010 issue Silicon Chip magazine. Altronics are selling a full kit of parts for the Intelligent Fan Controller (Part nbr K6120). This is an easy way to get everything that you need to build the controller including a pre programmed microcontroller and a printed copy of the full magazine article – ideal if you are not an electronics expert and just want to silence your computer.

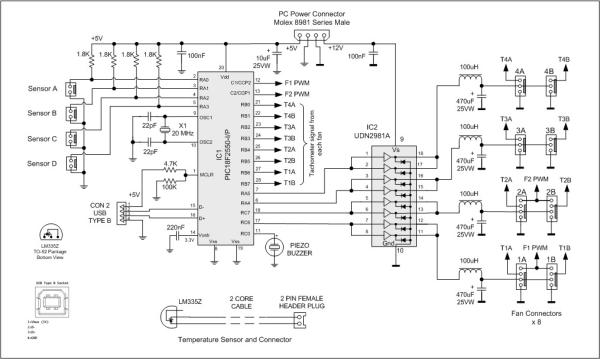

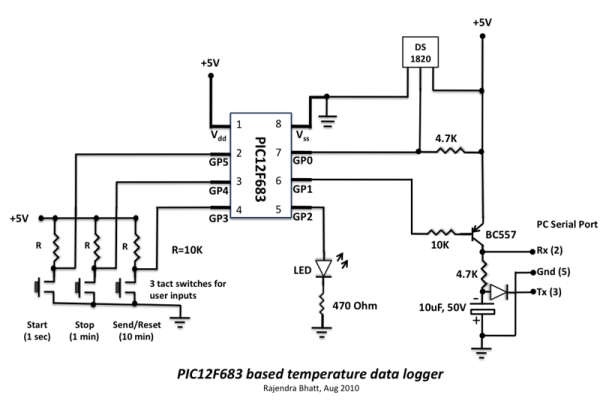

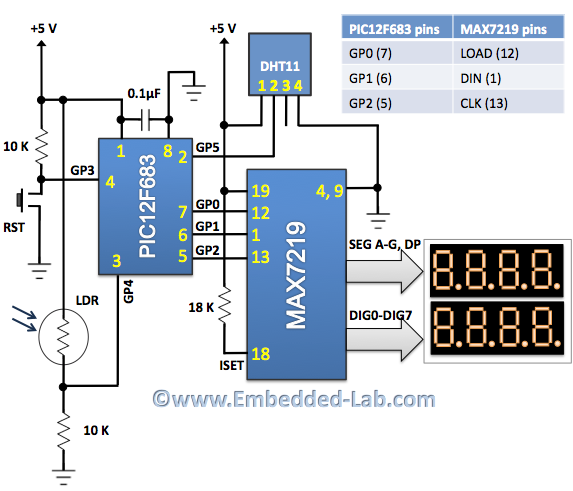

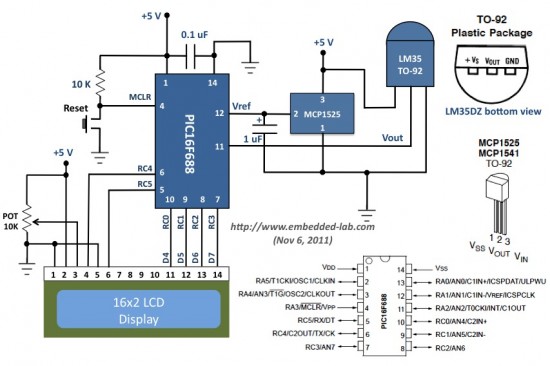

The Circuit

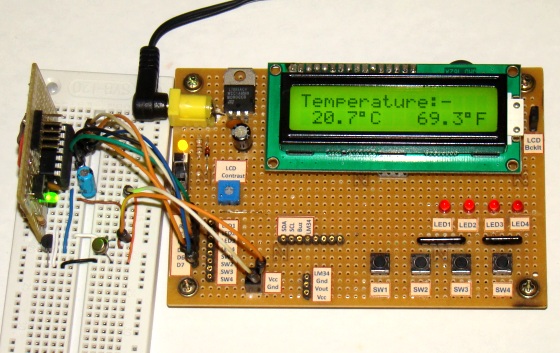

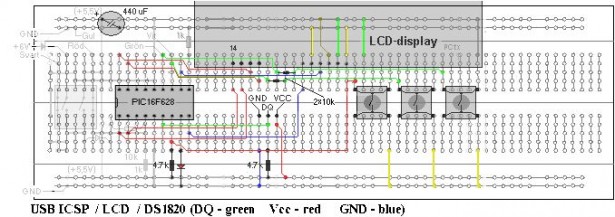

The circuit below shows just how simple the fan controller is. In the centre is a Microchip PIC18F2550 microcontroller, it reads the voltage from the temperature sensors LM335 (on the left) and controls the voltage converters on the right. It is by varying the voltage output of the converters that the microcontroller can control the speed of the fans.

Each voltage converter is implemented as a buck converter. The microcontroller generates a string of pulses on each output for each buck converter and, by varying the pulse width, the microcontroller can vary the output voltage. In this implementation the pulse rate is 2.5KHz and the pulse width varies between zero and 170µS to give an output between zero and 12V. Note that IC2 UDN2981A does double duty as a fast switch and a diode – both required in the buck converter design. For $2.20 this is a handy little chip.

Each voltage converter is implemented as a buck converter. The microcontroller generates a string of pulses on each output for each buck converter and, by varying the pulse width, the microcontroller can vary the output voltage. In this implementation the pulse rate is 2.5KHz and the pulse width varies between zero and 170µS to give an output between zero and 12V. Note that IC2 UDN2981A does double duty as a fast switch and a diode – both required in the buck converter design. For $2.20 this is a handy little chip.

For more detail: Intelligent Fan Controller. Part 1 – Schematic

The post Intelligent Fan Controller. Part 1 – Schematic using pic microcontoller appeared first on PIC Microcontroller.

For more detail:

For more detail: