Project Summary

An on-line monitoring system of temperature of conductors and fittings based on GSM SMS and Zigbee is produced in this project, by which the temperature of conductors and fittings can be monitored in real-time and some accidents caused by the increased temperature can be avoided. The principle and the feature of GSM SMS and Zigbee communication are analyzed. The construction of this system is outlined, and the force modal of calculating the variety of the sag due to the increased temperature of conductors is built. The Zigbee communication module is produced based on RF4CE standard. Finally, the software and hardware design of the online temperature monitoring unit of conductors and fittings are outlined.

Project Description

With fast development of economy in India, the demand of electricity is higher and higher, and the problem between lag of construction of network and inadequacy of transmission capacity becomes increasingly prominent, which exacerbates the unharmonious contradictions of development between power grids and power generation structure. Some provinces and cities have begun to take power limited policies to alleviate contradiction of the current electricity supply-demand, how to resolve this problem has become imperative responsibility for many power workers. Recently, in order to prevent overloading of transmission lines, domestic power system usually adopts the static, conservative transmission capacity value in design, which is a conservative static value based on the severest weather conditions.

However, such severe weather conditions rarely occurred, and it has resulted in the inefficient use of potential transmission capacities in most time. In the situation of “east-west power transmission, south-north power transaction, nationwide electricity interconnection”, long-distance, large-capacity and high-voltage transmission lines will be more and more. By 2010, the transmission capacity of some main lines of 500 kV will reach or exceed 1 GW. By 2020, the transmission capacity for most lines of 500 kV will reach 1 ~ 1. 5GW. Some normal current for heavy short lines will reach 2 GW, which will be near 3 GW in accidents. Now, according to the traditional technology, the transmission capacity can be increased only by adding transmission lines. However, it is becoming more and more difficult to build new transmission lines with the transmission lines increased.

However, such severe weather conditions rarely occurred, and it has resulted in the inefficient use of potential transmission capacities in most time. In the situation of “east-west power transmission, south-north power transaction, nationwide electricity interconnection”, long-distance, large-capacity and high-voltage transmission lines will be more and more. By 2010, the transmission capacity of some main lines of 500 kV will reach or exceed 1 GW. By 2020, the transmission capacity for most lines of 500 kV will reach 1 ~ 1. 5GW. Some normal current for heavy short lines will reach 2 GW, which will be near 3 GW in accidents. Now, according to the traditional technology, the transmission capacity can be increased only by adding transmission lines. However, it is becoming more and more difficult to build new transmission lines with the transmission lines increased.

From the perspective of sustainable development and environmental protection, we should pay more attention from power grids expansion to increase the potential transmission capacity of available transmission lines, and enhance the transmission capacity of power grids, so as to resolve the problems between high requirement of electricity and difficulty of new transmission line. In March 2005, the State Grids held a particular meeting about improving the transmission capacity of power grids in Beijing, the meeting pointed out that at the same time of building main electrified wire netting of super high voltage, we need actively and fully tap the potential of existing capacity. At present, some areas adopt the allowable temperature value of 70 to 80 or even 90. Properly increasing the allowable temperature of existing conductors can increase stable carrying capacity of transmission lines, thereby the normal transmission capacity is improved. The method is a breakthrough of current technical regulations, the impact caused by improving conductor temperature on conductors, the mechanical strength and the lifespan of matched fittings, the increase in sag and so on should be studied. In addition, if the conductor temperature and the sag can be real-timely monitored, the dynamic regulation of the transmission capacity, such as day and night, cloudy and sunny, summer and winter under the different environmental conditions can be realized to improve the transmission capacity. In order to meet these demands, an on-line monitoring system of temperature of conductors and fittings based on GSM SMS and Zigbee is studied and developed in this paper.

Introduction to GSM SMS, ZigBee and LM35

A. GSM SMS

GSM (Global System Mobile Communications) is a global digital mobile communication system, whose coverage is the most widely, phone owners is the largest, and reliability is very high. SMS (Short Message Service) is a kind of short message transmitted. In fact, the information transmission is achieved by receiving and sending text message in the businesses center between mobile phones and other short message carriers, and the businesses center is an independent operating system of GSM network whose main function is submitting, storing, and transferring short message. SMS is a special and important service as well as calling for users by GSM system. In this project, a self-designed industrial GSM module is selected to finish the transmission and the decoding of the monitoring data through AT command and coding of short message PDU (Protocol Data Unit).

B. ZigBee

ZigBee wireless network technology is a new standard launched and made by ZigBee Alliance. The alliance, founded in August 2001, is a fast-growing and non-profit organization, and it aims is to provide consumers with more flexible and easier electronic products. The second half of 2002, four large corporations including the British company Invensys, Mitsubishi Electric Corporation, Motorola and the Dutch giant Philips Semiconductor Corporation jointed together to announce that they would join the “ZigBee Alliance” to invent the next-generation wireless communication standards named “ZigBee”, which became a significant milestone in the development process. In October 2004, the ZigBee Alliance announced a version 1.0 of ZigBee protocol, and in December 2005 version 1.1. ZigBee uses free frequency bands of 2.4 GHz and 900 MHz, and its transmission rate is 20 kbps to 250 kbps. In this paper, the perfect chip cc2430 is selected to design the wireless hardware platforms of ZigBee, a standard ZigBee wireless network module is produced, and a reduced version of ZigBee wireless network protocol is programmed. The Zigbee module and protocol have been successfully applied to power system, medical and some other fields.

ZigBee is the set of specs built around the IEEE 802.15.4 wireless protocol. The IEEE is the Institute of Electrical and Electronics Engineers. They are a non-profit organization dedicated to furthering technology involving electronics and electronic devices. The 802 group is the section of the IEEE involved in Information technology—Telecommunications and information exchange between systems—Local and metropolitan area networks including mid-sized networks. Group 15.4 deals specifically with wireless networking (Wireless Medium Access Control (MAC) and Physical Layer (PHY) Specifications for Low-Rate Wireless Personal Area Networks (WPANs) technologies.

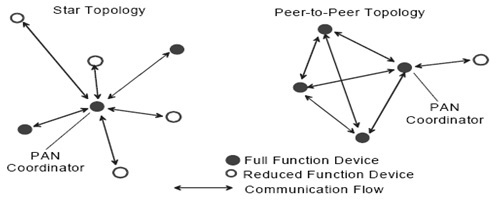

Network Topologies

Depending on the application requirements, an IEEE 802.15.4 LR-WPAN may operate in either of two topologies: the star topology or the peer-to-peer topology. Both are shown in Figure. In the star topology the communication is established between devices and a single central controller, called the PAN coordinator.

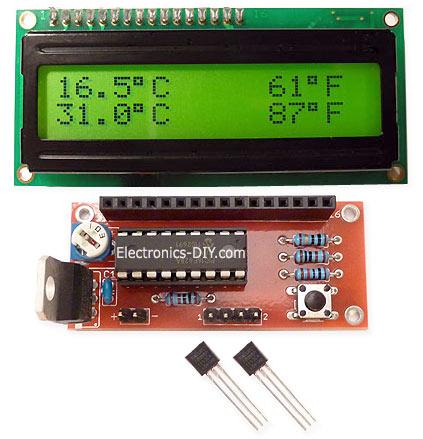

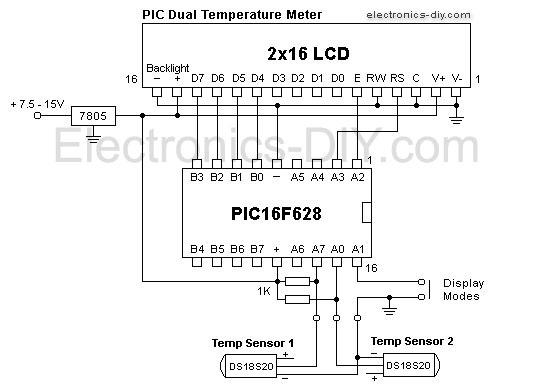

Temperature Measurement

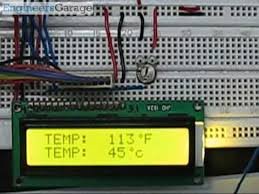

Temperature Measurement

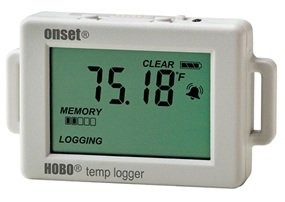

Temperature can be measured via a diverse array of sensors. All of them infer temperature by sensing some change in a physical characteristic. Six types with which the engineer is likely to come into contact are: thermocouples, resistive temperature devices (RTDs and thermostats), infrared radiators, bimetallic devices, liquid expansion devices, and change-of-state devices.

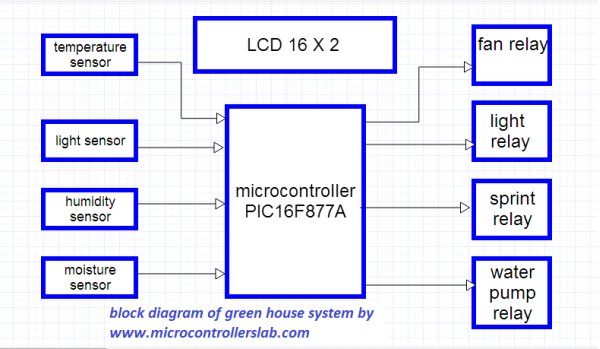

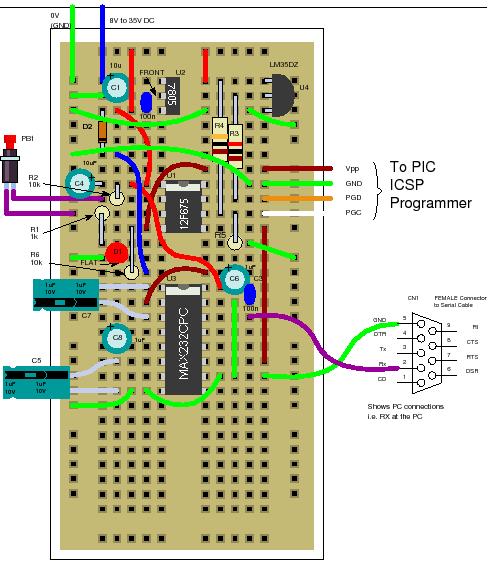

The Overall Structure of Online

Monitoring System

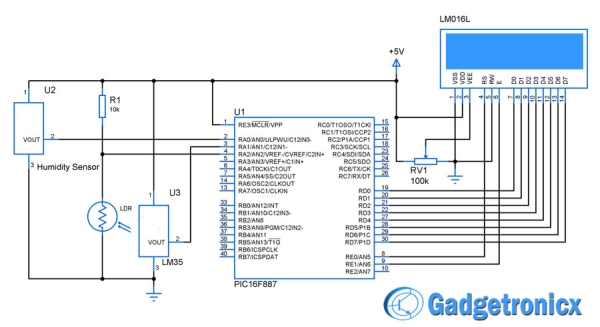

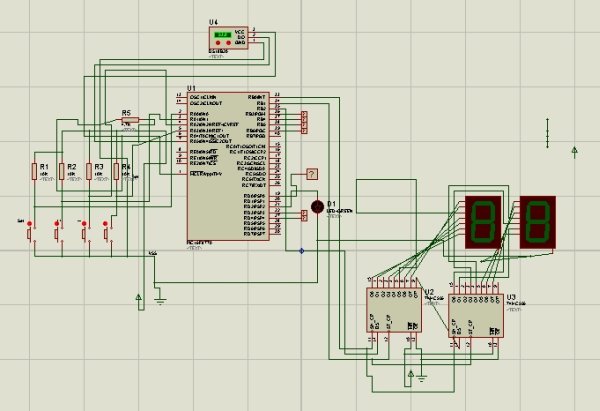

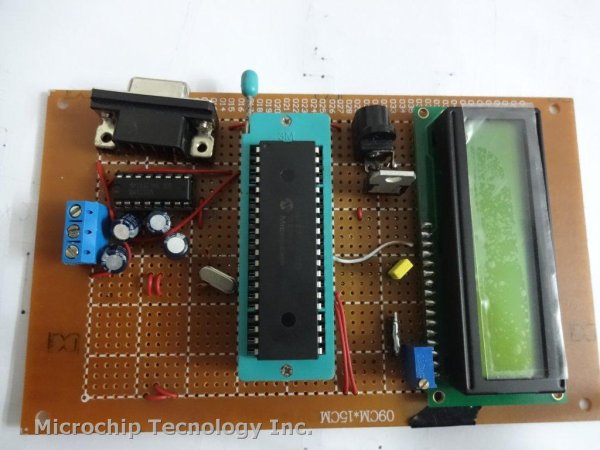

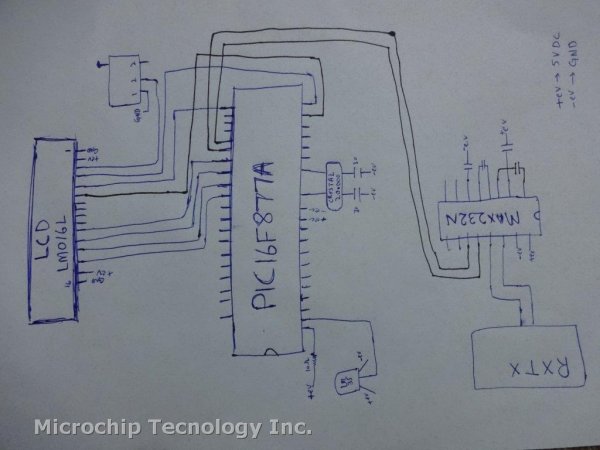

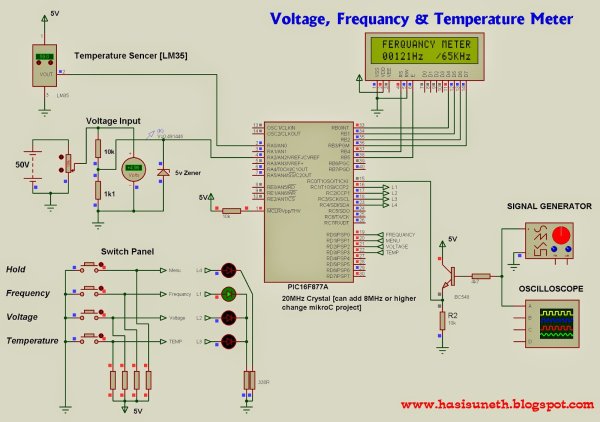

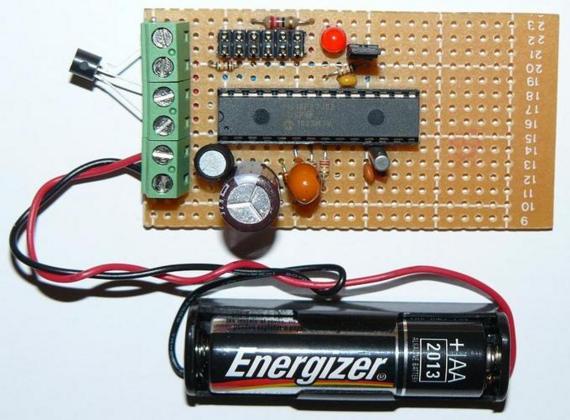

The online monitoring system of temperature of conductors and fittings based on GSM SMS and Zigbee is mainly composed of the municipal monitoring center, the communication unit, the temperature monitoring unit and the expert software, the topology of system is shown in Fig.1. The communication unit is installed on the tower with both GSM and Zigbee communication modules, and the temperature monitoring unit on the corresponding conductors with the same potential.

For more detail: Online Monitoring of Temperature of Conductors Using Zigbee and GSM

Current Project / Post can also be found using:

- projects of temperature measurement devices

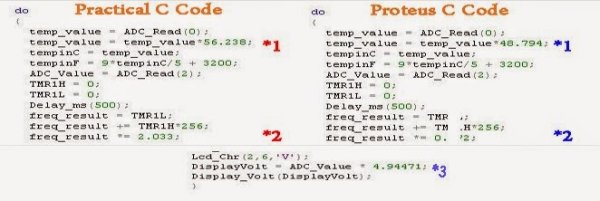

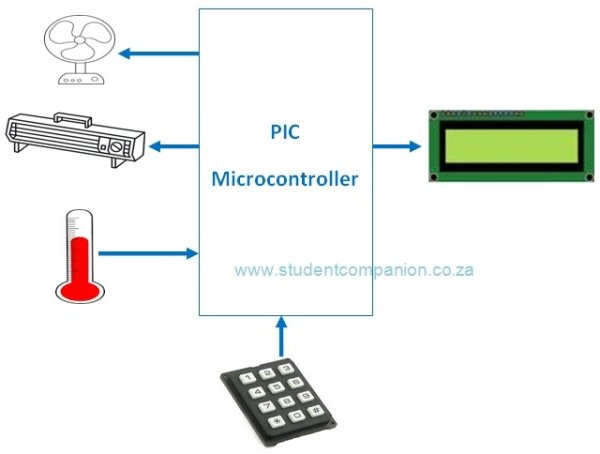

- Temperature controller Using PIC 16f877a DS18B20 rs232

- temperature controller using pic 18F4550

- temperature controller using pic microcontroller project

The post Online Monitoring of Temperature of Conductors Using Zigbee and GSM appeared first on PIC Microcontroller.